Ultimate Pipe Inspection System 100 mm to 155 mm

Tube and Bore Inspection 100 mm to 155 mm

Non-Contact Laser Measurement

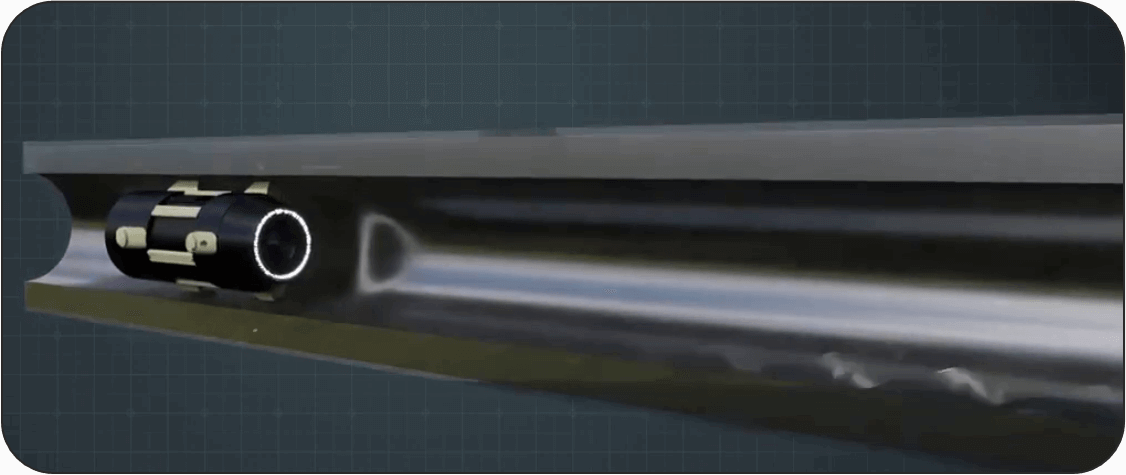

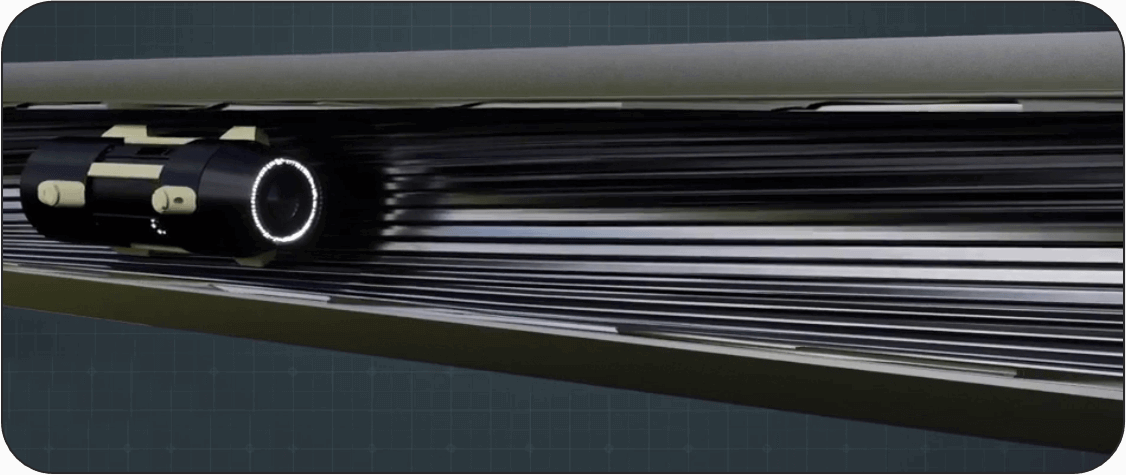

The Ultimate Pipe Measuring and Inspection system for middle diameters (Laserscan Ultimate) is the most compact unit available. The system is able to measure Smooth, Profiled and Rifled Pipes / Barrels & Bores/ Tubes & Pipes Stators & Extruders Precise Cylinders with inner diameters from 100 mm to 155 mm. Pipe length is up to 14 mtrs.

Ultimate Pipe Inspection System (UPIS) 100 mm to 155 mm

For Middle Diameters With Rotating Laser Scanner Front Video And Rangefinder.

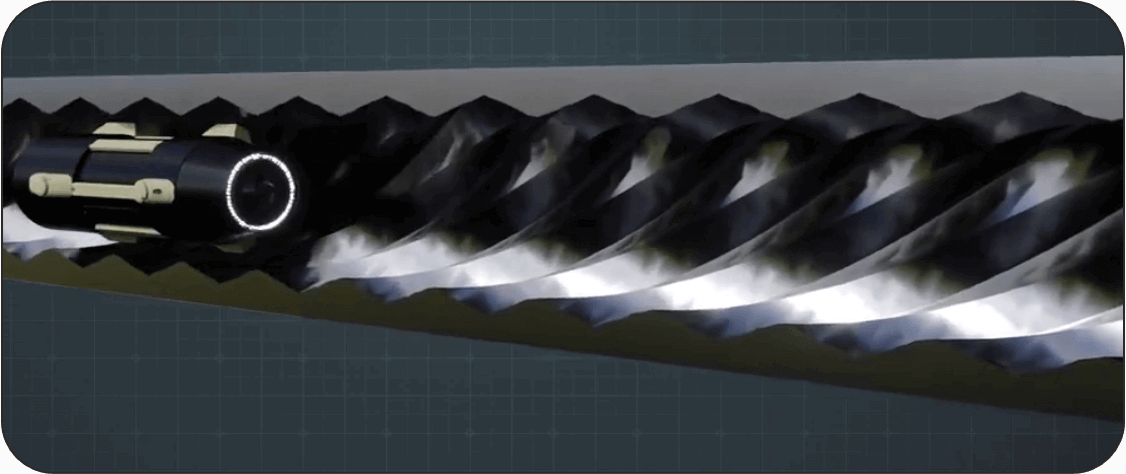

The system provides a forward view camera and a side view colour (white LED) camera, the camera heads can be switched between views to identify Damage / Verdigris / Copper Deposits / Firing Residue on the rifling of the barrel. The monitor can also provide picture-in-picture for precise location of damage in a barrel.

The system can be equipped with non-straightness module to perform laser-alignment using integrated PSD sensor and external laser emitter.

Camera Specification

| Camera | |

| Hi-Resolution: | With adjustable focus |

| All-Round Visibility: | Panoramic photograph |

| Camera Angle Frontal: | 180° degree |

| Front Camera: | Panamorph lens |

| Side Camera | Autofocus |

| MP: | 5 MP |

| Full Resolution: | 2560 x 1920 Pixels |

| Zoom: | Digital |

| LED Lighting: | 3 Channel LED lighting |

Rotating Laser 2D Scanners

The probe has five different measurement channels: rotating laser 2D scanner(s), encoder, inclinometer, distance gauge, and straightness detector. It combines the sensors data to get the full 360 ̊ cross sectional profile of the pipe or stator and finally the point cloud of the inner surface for the full length of the bore. Based on the exceptional number of precisely measured points, diameters and lobe parameters are calculated.

- Inspection and Identify

Any smooth pipes , profiled pipes, and smooth bores and barrel 100 mm to 155 mm damage with magnification. - Measures the Following Parameters

Rifling.

Flank angles.

Lands and grooves. - Identify and Measure

Surface defects.

Cracks and pitting.

Holes and barrel wear.

Erosion and corrosion of the gun barrel.

Everything larger than 0.01 can be measured.

Poles engraved with depth measurement graduations. - Results

The results are also exported to computer for analysis at later date.

Digital grid overlay for determining the size of artifacts and objects.

Measurements displayed in real time with location and bore information. - Accuracy

It combines the sensors data to get the full 360 ̊ cross-sectional profile of all smooth bore and rifled barrels, with a +/-0.01 mm accuracy.

Optional Extras

- Barrel or Bore Straightness

Will check non-straightness of all barrels and bores. - Chromium Coating

The sensor measures the barrel and bore coating thickness. - Self Moving Option

Converts system to automatic mode.

Accuracy Of Borescope

| Inner Pipe Diameter: | ± 0.01 mm |

| Deviation From Roundness: | ± 0.01 mm |

| Straightness: | ± 0.01 mm |

| Deviation Of Shape Of The Profile: | ± 0.03 mm |

| Width Of The Elements Of A Profile: | ± 0.05 mm |

| Custom Measurement Range: | 100 mm to 155 mm |

3 Probe Sizes Available

| Complete Pipe Inspection & Measurement System (PIMS) 76 mm to 240 mm | System Configuration |

|

|

Optional Extra

We can apply this at the manufacturing build process.

- NanoTech Circuit Coating

Using BCS NanoTech circuit board protection, you can protect the borescopes circuits, PCBs, and other electrical components from damaging elements.

Ongoing protection of electrical and electronic equipment from exposure to all forms of water; steam, humidity, condensation, fog, rain, flooding, chlorinated and salt water.

This superior protection prevents the need for costly circuit replacements. Our NanoTech Circuit Coating is also ideal for protecting and waterproofing borescope expensive electronics.

- NanoTech Metal Protection

Can also be applied locally, in the field or maintenance depot.

NanoTech Metal is a clear, nanotechnology enabled coating engineered specifically for all types of metal surfaces. The coating forms an invisible, long lasting bond with the surface to repel water and prevent stains and the build-up of dirt and other contaminants.